Description

| Number of Conductors | >10 |

| core | 2-146 |

| cable diameter | 13.7-20.9 |

| RTS | 1000/3000N |

| Span | |

| MAT | |

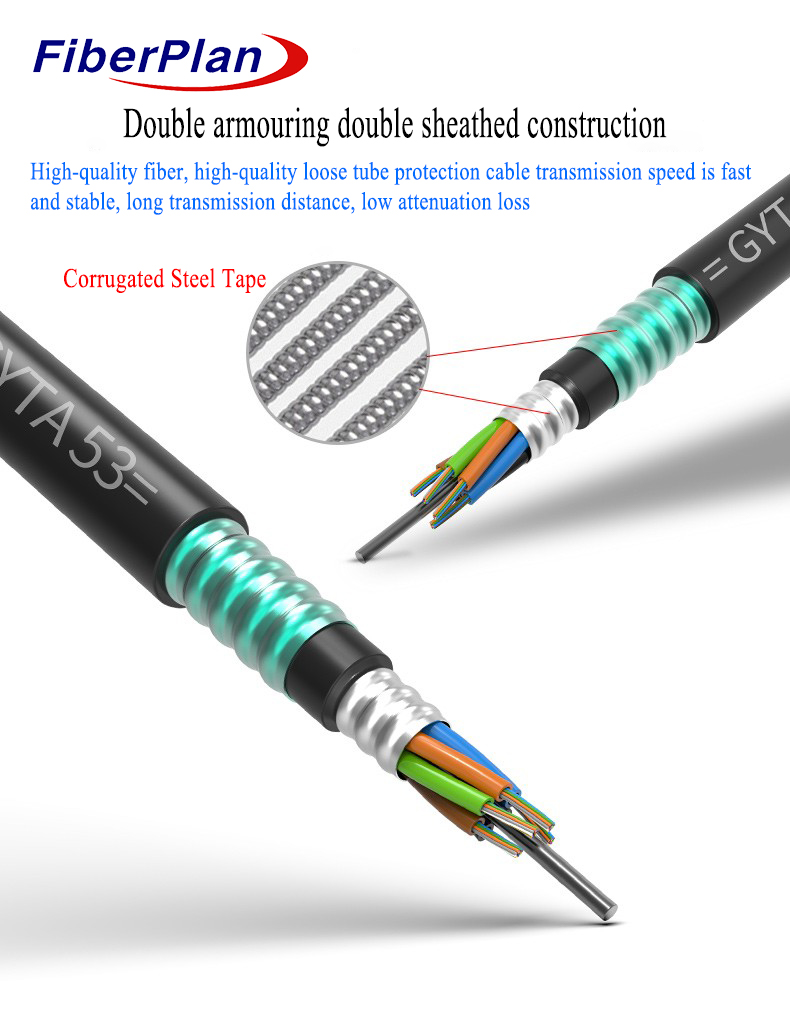

| reinforcement | ALP+PSP |

| Voltage | |

| cable weight | 190-373kg/km |

| Bending | 10/20D |

The fibres,250μm,are positioned in a loose tube made of a high modulus plastic.

The tubes are filled with a waterresistant filling compound.A steel wire,sometimes sheathed with polyethylene(PE) for

cable with high fiber count,locates in the center of core as a metallic strength member. Tubes (and fillers) are stranded

around the strength member into a compact and circular core. An Aluminum Polyethylene Laminate (APL) is applied

around the cable core,which is filled with the filling compound to protect it from water ingress,then, the cable core is

completed with a PE sheath .After the PSP is longitudinally applied over the inner sheath,the cable is completed

with a PE outer sheath.

• Applications:

1. Duct, Aerial, Direct bruied.

2.High speed optical routes in buildings(FTTX)

•Characteristics:

1. Good mechanical and temperature performance

2. High strength loose tube that is hydrolysis resistant

3. Specially designed compact structure is good at preventing loose tubes from shrinking

4. Special tube filling compound ensure a critical protection of fiber

5. PE sheath protects cable from ultraviolet radiation

6. Steel wire used as the central strength member

7. Loose tube filling compound

8. APL moisture barrier

| Fiber count | Nominal diameter (mm) | Nominal weight

(kg/km) |

Max fiber per tube | No. Of (tubes+fillers) | Allowable

tensile load (N) |

Allowable

load resistance (N/100mm) |

||

| Short term | Long term | Short term | Long term | |||||

| 2-36 | 13.9 | 202 | 6 | 6 | 3000 | 1000 | 3000 | 1000 |

| 38-72 | 15.1 | 241 | 12 | 6 | 3000 | 1000 | 3000 | 1000 |

| 74-96 | 17.1 | 290 | 12 | 8 | 3000 | 1000 | 3000 | 1000 |

| 98-120 | 18.6 | 333 | 12 | 10 | 3000 | 1000 | 3000 | 1000 |

| 122-144 | 20.2 | 381 | 12 | 12 | 3000 | 1000 | 3000 | 1000 |

| >144 | Design according to your requirement. | |||||||

• Packing & Shipping

Rolled by wooden drums. 2km-3km per drum or other required.

2. Sheath mark

The following printing is applied at 1-meter intervals.

a. Supplier: Fiberplan or as cuctomer required

b. Standard Code(Product Type, Fiber Type, Fiber Count)

c. Year of manufacture: xxx

d. Length marking in meters

Reviews

There are no reviews yet.